Introduction:

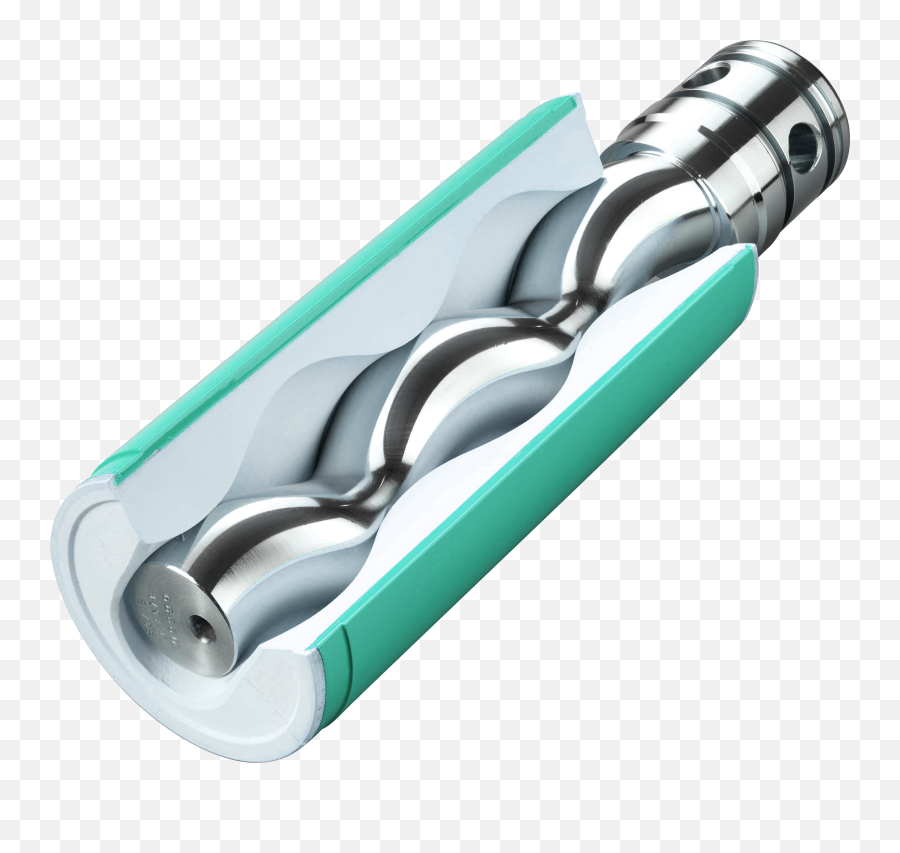

Screw pumps are widely used in many industrial applications to pump fluids. However, over time, the rotor of a screw pump may wear out or become damaged, resulting in reduced pump efficiency or even failure. In this article, we will provide you with a step-by-step guide on how to replace a screw pump rotor, and optimize it for SEO by using relevant keywords throughout the article, such as “screw pump rotor”, “maintenance”, and “replacement”.

Section 1: Importance of Screw Pump Rotor Maintenance

In this section, we will discuss the importance of regular maintenance of screw pump rotors, and how it can improve the pump’s performance and longevity. This section will include keywords such as “screw pump rotor maintenance”, “preventative maintenance”, and “rotor wear and tear”.

Section 2: Step-by-Step Guide on Replacing a Screw Pump Rotor

This section will provide a detailed guide on how to replace a screw pump rotor, including steps such as shutting down the pump, removing the pump casing, inspecting the pump components, installing the new rotor, and testing the pump. It will include relevant keywords such as “screw pump rotor replacement”, “disassembly process”, and “installation process”.

Section 3: Tips for Maintaining Screw Pump Rotors

In this section, we will provide tips and recommendations for maintaining screw pump rotors, including regular inspections, lubrication, and cleaning. This section will include keywords such as “screw pump rotor maintenance tips”, “lubrication”, and “cleaning”.

Conclusion:

In conclusion, regular maintenance and replacement of screw pump rotors are crucial for ensuring the continued operation and efficiency of the pump. By following the step-by-step guide and tips provided in this article, you can optimize the maintenance of your screw pump rotor and extend the lifespan of your pump.