Overview

The sludge eccentric helical single screw pump is a closed screw pump of internal gearing belonging to rotate cubage pump because of its adaptability for medium. Stable flow, well suction capacity, low-pressure fluctuation. It transports all kinds of flow mediums and the medium with high viscosity.

Working Principle

The sludge eccentric helical single screw pump is an inner gearing rotary pump; the main working parts are the eccentric screw (rotator) and static bush (stator) because of the particular geometry shape. From several single sealed rooms, pump the medium from the suction port to the discharge part continuously and regularly.

Application

Its speed can be switched freely, and its output-rated pressure can be increased by its level. The pumps can be widely used in many different areas.

Especially to be emphasized in the application in plants of:

Environmental protection:

Oil-water separator, plate, and frame filter press for conveying industrial sewage, domestic sewage, and sludge and filth, which contain solid particles and short fibers

The shipping industry:

The bottom of ship cleaning plants for conveying oil-water, oil residue, and oily sewage.

The petroleum industry:

oil delivery

Recently, it successfully pumped a mixture of oil and water, coal field gas, and water from kilometers deep underground, which significantly reduced the cost. Then you can use the screw pump to pour polymer into layers to increase the efficiency of the exploitation of oil fields by late time.

The medical and daily health product industry:

Plants for conveying dope, oil-water emulsion, and salving cosmetics.

The canned food industry:

Plants for conveying viscous starch, edible oil, honey, syrup, fruit puree, cream, minced fillet, and minced meat and their residues.

Brewing industry:

Plants for conveying viscous liquid fermentation, thick lees, the residue of food products, all kinds of syrup and paste, and mucus, which contain blocky solid matter.

The construction industry:

Plants for conveying cement mortar, lime mortar, coating material, and other pasty material.

The mining industry:

Plants for discharging groundwater and sewage, which contain solid particles to the surface.

The chemical industry:

Transport all kinds of suspension, grease, colloid, and adhesive

Specification

|

Flow rate

|

Up to 45 m³/h

|

|

Head

|

Up to 120 m

|

|

Speed

|

max 1450 rpm

|

|

Temperature

|

Max 120 ℃

|

|

Casing pressure

|

Up to 1.2 MPa

|

|

Shaft seal

|

Mechanical seal/Gland packing seal

|

|

Material

|

Cast iron/Stainless steel

|

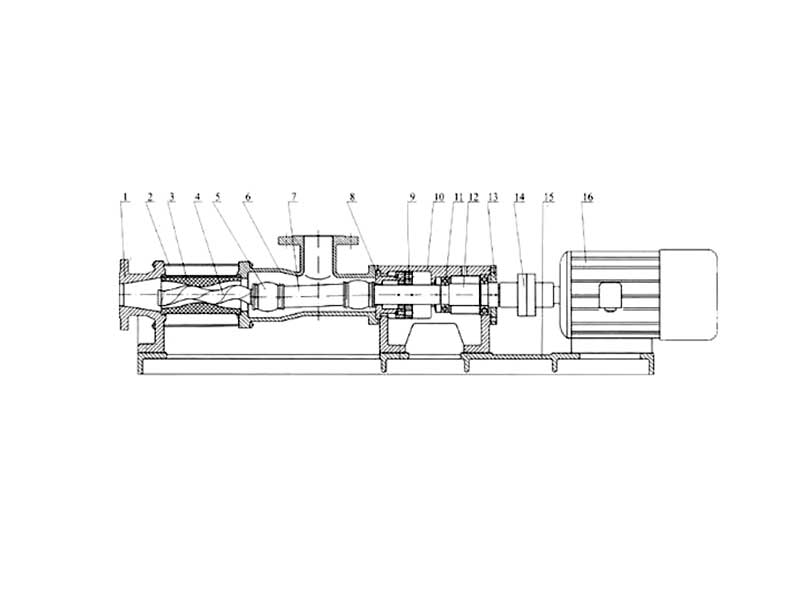

Structure and datasheet

|

1. Outlet

|

2. Tie Rod

|

3. Stator

|

4. Rotor

|

|

5. Universal Joint

|

6. Feed Axis

|

7. Coupling Rod

|

8. Grand

|

|

9. Bearing

|

10. Bearing Block

|

11. Bearing

|

12. Drive Shaft

|

|

13. Bearing Cap

|

14. Coupling

|

15. Basement

|

16. Motor

|